For the last two decade, we have remained an agile, customer – focused organization that provides our customers with the most highly experienced and certified engineers in the industry.

Our detailed knowledge of in – demand technologies and clear vision of customer goals, allows us to execute tailored services that meet or exceed customer requirements and needs.

This includes developing partnerships and alliances with vendors integrator’s and other service providers to deliver streamlined and complete solutions.

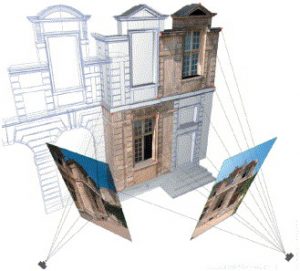

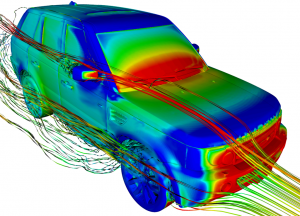

Quality Solutions also prides itself on providing a complete 3D experience for its clients through deployment of cost – effective CAD/CAM/CAE Solutions.

We have the capability to implement a complete Product Development Solution ( PDS ) that will enable an enterprise wide, secured and quick visibility of its manufacturing process to inside as well as outside stake holders increasing growth and profitability.

3D Engineering Solutions by Industry

To Make an Appointment

3D ENGINEERING SERVICES

3D ENGINEERING SOLUTIONS

TRAINING COURSES

3D As Built BIM

REVERSE ENGINEERING

Quality Control & Inspection

In this course you will learn how to examine products and materials for defects or deviations to met certain predetermined standards of manufacturer or industry.

CAD | CAM | CAE

Design for your training requirements by seeing the programs available for SOLIDWORKS products, including SOLIDWORKS, SOLIDWORKS Simulation, SOLIDWORKS PDM, and SOLIDWORKS Composer.

Project Data Management

In PDM training courses you will learn the core skills and concepts needed to utilize SOLIDWORKS PDM Standard or Professional effectively. PDM training helps to focus on managing design data and development.

OUR CLIENTS